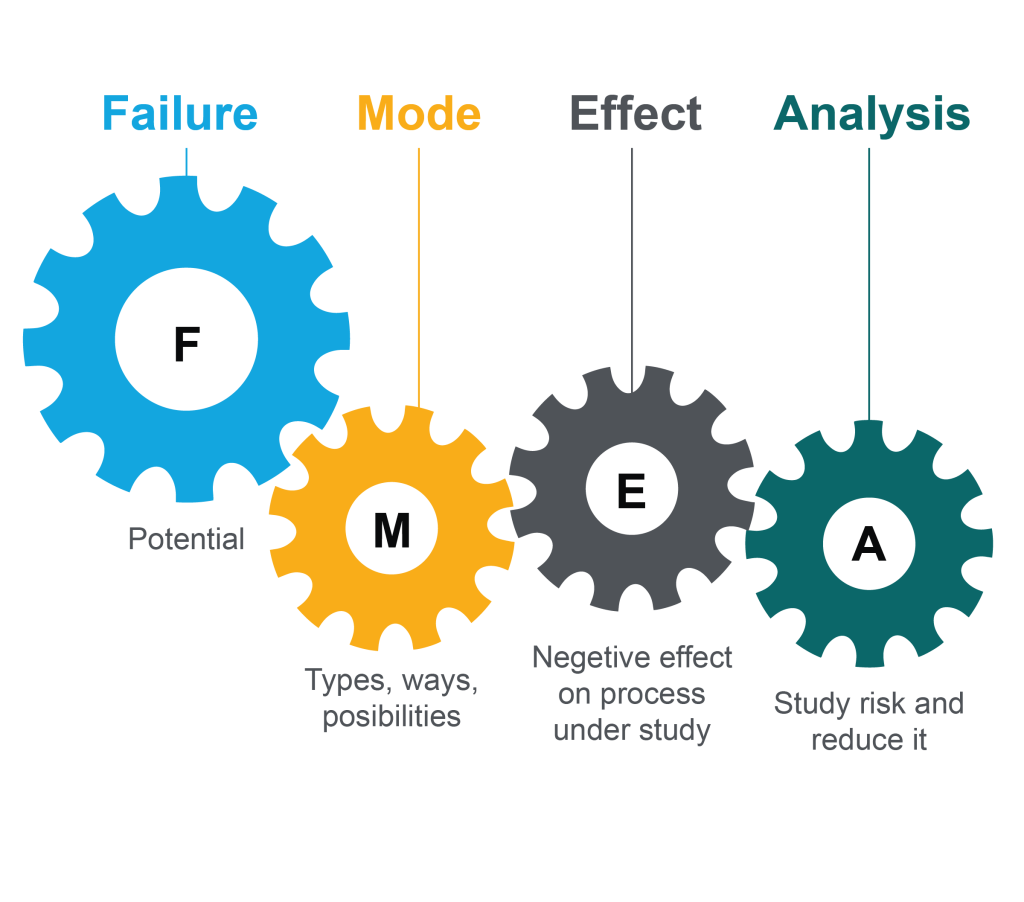

Our services are designed to proactively identify and mitigate potential failures in your processes or products. Our experienced team employs a systematic approach to analyze potential failure modes, assess their effects, and determine the likelihood of occurrence.

| Benefits accrue to business and customers | |

| Reduces risk of failure | Reduces Costs of Non-quality (CoNQ) |

| Enables clear communication of failure mitigation priority setting | Fewer development resources needed to address CoNQ |

| Increases stakeholder buy-in | Reduces time to market |

| Provides knowledge database | Complies with FDA Design Controls definitions |

| Increases customer satisfaction | Provides input for optimized failure diagnostics |

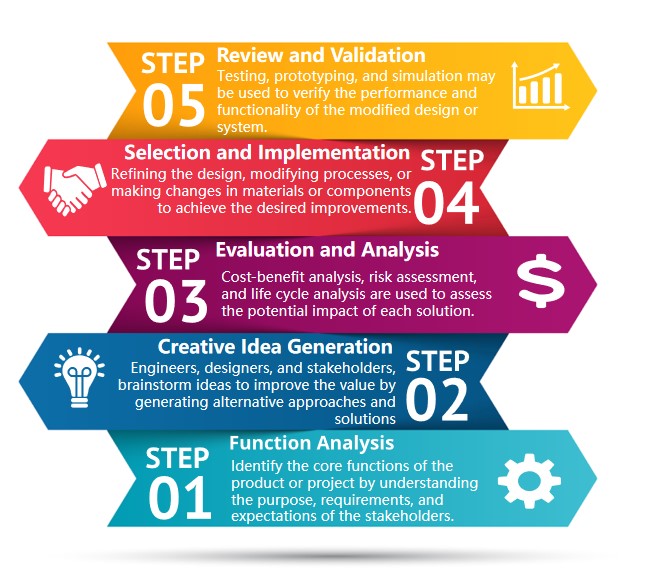

Value engineering is a systematic approach used to analyze and improve the value of a product, system, or project by examining its functions and reducing costs while maintaining or enhancing performance and quality. Our primary goal of value engineering is to maximize value for the end user or customer while minimizing unnecessary expenses.

Rework adds a level of undesirable variation to the Process both when taking products out for repair and when trying to reintroduce them. In cases where reworks become a regular occurrence, this can even drain away manpower as employees get specifically assigned to work on them. We provide complete rework and repair solutions to effectively manage production ,without affecting the productivity.